S-7 GEAR SOCKET BOLT HOLE REINFORCEMENT

2012/01/10

Owners who operate on wheels

have found that the ¼” hole for the bolt

that retains the gear leg in the socket will enlarge due to torque on the gear

leg. Current kits have additional plates welded on to the sockets to provide

thicker material to help resist this wear.

Because welding on a completed

airframe is not something everyone wants to tackle, there have been other

solutions in the form of bolt on shells. This is another, simple way of doing

it.

This is a chunk of 1 5/8 OD

steel pipe with a 1 3/8 ID that nicely fits over the gear socket:

Mark off two, 2” lengths then

drill a ¼” hole through each length in the center. Cut through, from both sides

but only 95% on each 2” length leaving two small bits of the circumference to hold

everything together. To ensure you keep matching halves together put in cuts or

punch marks to allow you to identify each side of both 2” lengths. Next mark

two lines along a plane perpendicular to the holes and cut each 2” length in

half. The additional length on the pipe

makes a handle for pushing it into the band saw.

Clean up, paint, then coat

inside with JB Weld and install. Just rough up the paint on the socket where

the shells will sit and tighten the gear leg bolt. The two gear clamps add additional

tension while the JB Weld hardens.

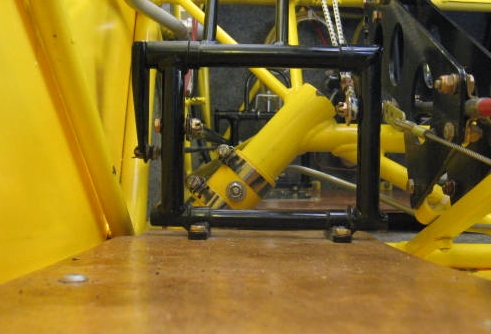

Here is the right side:

And the left: